Building a Hurdy Gurdy

Story of a hurdy gurdy - Baptiste Schieberlein

Building the pegbox and stating the varnish

Hi everybody!

Today we will see how I made the head and also the start of the French polish!

But before starting let me introduce you a newcomer at my home: A Kity 613 band-saw that I will use from now on

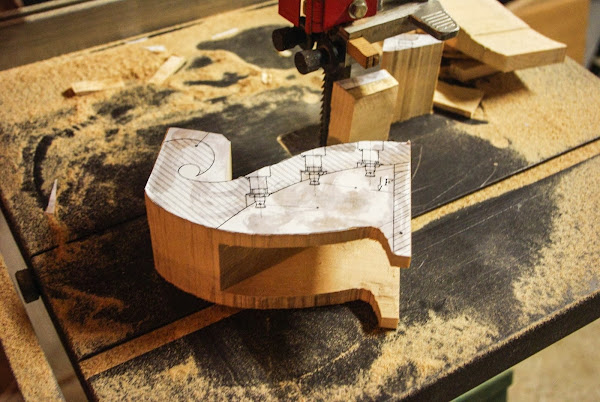

Let’s start with the head. I took a wood cut of 150*100*100mm. I hollow out the bottom of the head with a circular saw (I didn’t took pictures while doing it because I didn’t do it at home).

After that I used my new band-saw to cut the outlines.

I drilled the peg holes using a lot of little wedges in order to have the holes in the correct axis.

I wanted to make a carved head like traditional hurdy-gurdies. But as I never did any wood carving before, I thought that I will try to make something not too ugly, if it is ok I will keep it, otherwise I can just cut the end of the piece!

I am still far from real carved hurdy-gurdy head, but I still very satisfied for a first time so I choose to keep it!

After the head I prepared and cut the tailpiece:

The tailpiece once finished:

Afterwards I could start the sanding of all the pieces of the hurdy-gurdy. I started with grit 100 then 180, and 500 and at last 1000. (I didn’t take picture as I thought that it wasn’t very interesting to see some dust).

Once everything nicely sanded, I put a linseed oil coat on all the pieces and I left it dry.

After that I had to put a wood sealer. I sprinkled all the pieces with some pumice powder, and with a rubbing pad lubricated with alcohol and linseed oil I rub the whole surface by making circles:

I also prepared a bottle of shellac: I put shellac flakes to about a third of the bottle and I filled the rest with 95° alcohol. After a few days here is the result:

For doing the French polishing I used a rubbing pad that I filled regularly with shellac and I also put a drop of petrolatum oil so the pad will glide nicely on the wood.

After one coat of French polish:

Once the first coat as dried, I sprinkled the hurdy-gurdy with some pumice powder again and I rubbed it with some newspaper put into a ball in order to level out the varnish.

That is all for today, I still need to put 7 or 8 other coats of shellac… and then I will be able to glue everything together!

To the next post!